|

|

|

|||||||||

|

[1] [2] |

|

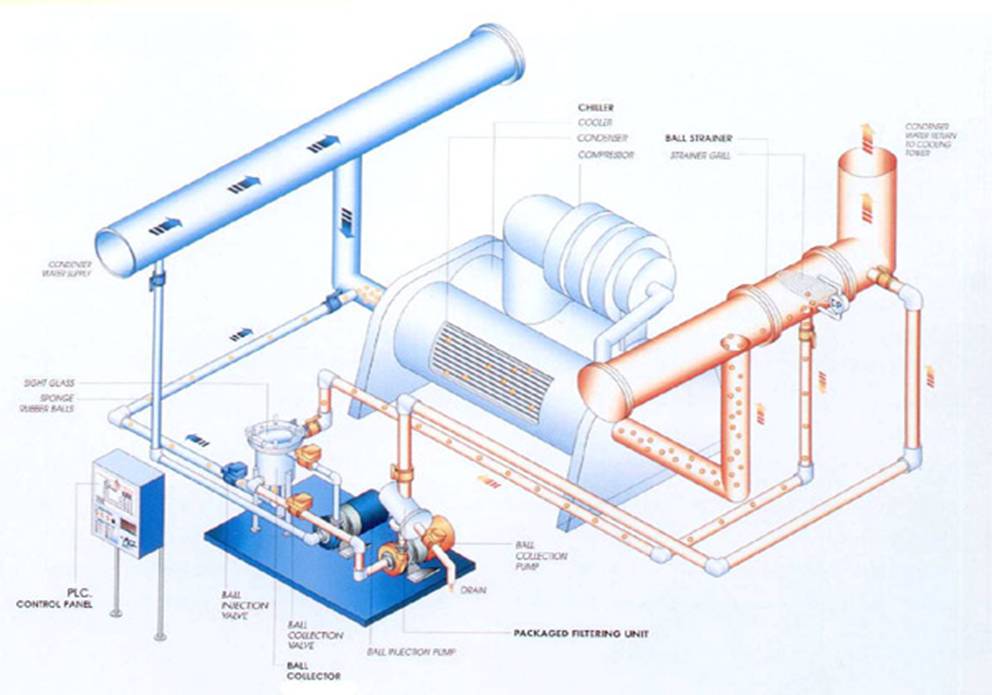

BALL GUARD In most cases, electrical consumption of the chiller is a large proportion of the total kilowatts consumed throughout the year. In fact, air conditioning systems for high-rise building or manufacturing plants such as office towers, hotels, hospitals, department stores account for 40-60% for all electrical costs. Most people are unaware that the accumulation of impurities in the chiller's condenser tubes can decrease heat transfer by more than 30%. Where do these impurities come from? Because condenser water cooling systems are open to the environment, the water in them soon become dirty. During the process of cool down, water in the cooling tower absorbs dust and other impurities that are present in the air. Environmental condition such as location of the premises are season, also help to from slime and algae. Chemicals left behind from the water treatment process can also aggravate the situation. When all these condition occur, fouling mechanisms form on the tube wall, restricts the flow of water and effects the heat transfer causes higher power consumption. In general practice, once or twice a year OFF-LINE manual cleaning of the chiller is needed to rid condenser tubes of fouling mechanisms. Wasted time and expensive maintenance can only ensure optimum performance for a short time. As soon as the chiller unit is returned to service, performance begins to deteriorate. Also, during manual condenser tubes cleaning and damage to the tube wall occurs.

The benefits of using Ball Guard on-load tube cleaning system. Ball Guard provides you with the best possible solution for energy conservation at the chiller plant.

|

[1] [2] |

|

|